The economic efficiency of a gas station is largely determined by the capabilities of the equipment used. The Shelf 300-2 fuel dispenser has a gantry design and is distinguished by high performance and reliability. The unit is designed for the simultaneous filling of two vehicles with liquid fuel, located on both sides of it.

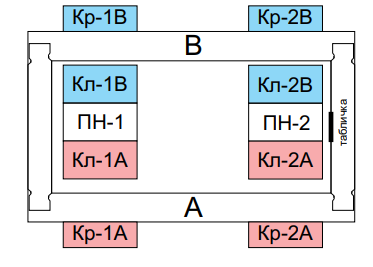

Schematic arrangement of the pump

The Shelf 300-2 dispenser is equipped with two pairs of dispensing hoses and can be used to dispense one of two types of fuel. The unit is designed to operate with liquid fuel with a specific viscosity of 0.55 to 40.0 mm2 / s, which include kerosene, diesel fuel (biodiesel) and gasolines with different octane numbers. The complex measures the volume of supplied fuel, calculates the cost taking into account the set price and displays the result on the display.

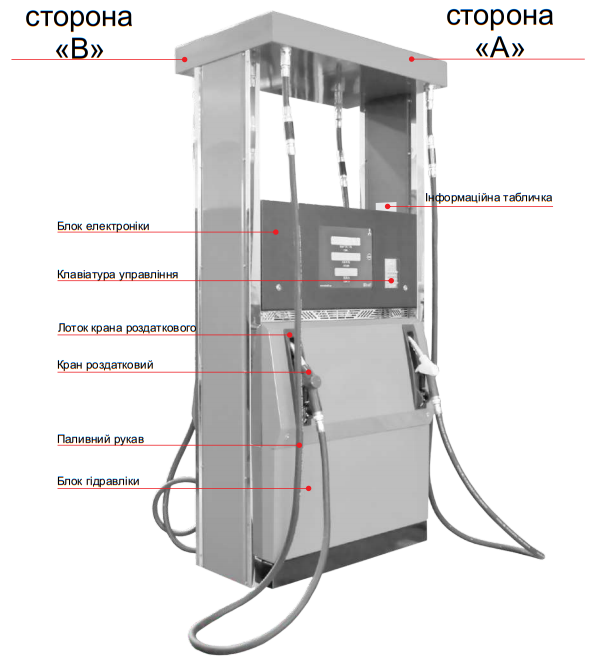

The offered fueling dispenser has a space frame, in which the hydraulic and electrical parts are located. On the outer panel in the upper part, a scoreboard and a remote control unit are installed, below there are two holders for dispensing taps. The installation includes the following elements :

- Two centrifugal self-priming pumps with electric drive, cleaning filter, check valve.

- Two four-piston fuel volume meters.

- Electronic calculating unit based on processor and pump control unit and other functions.

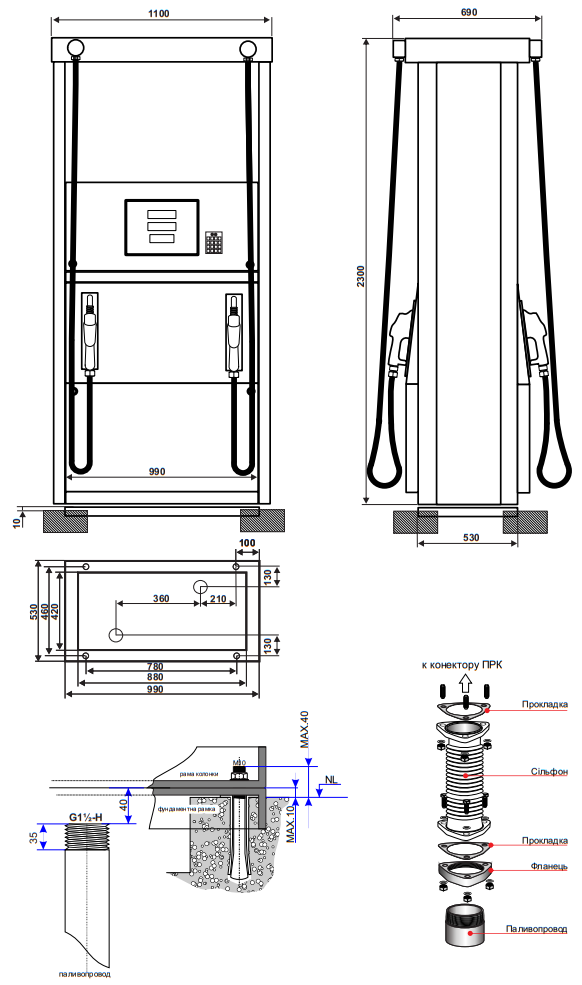

Wiring diagram for fuel dispensers with built-in pump

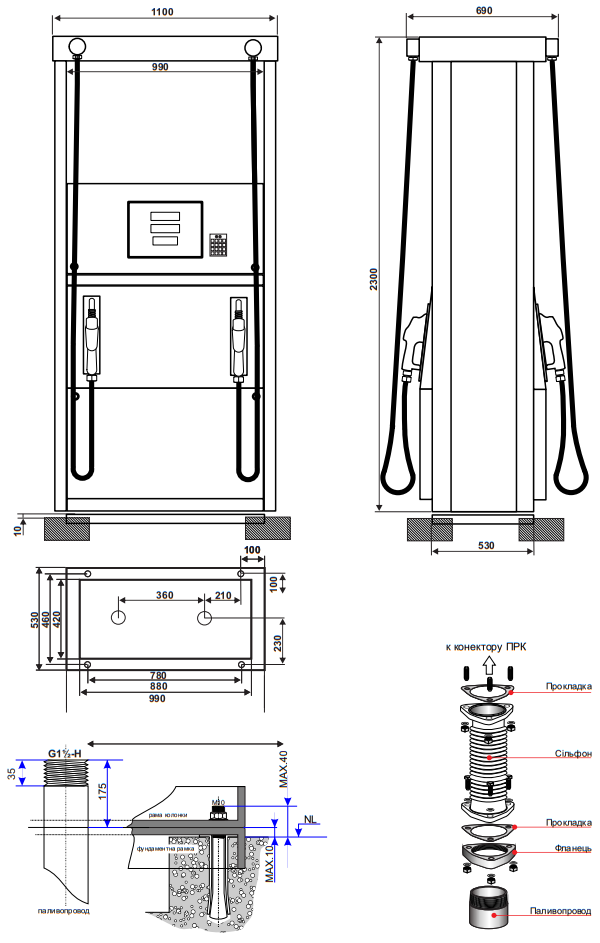

Wiring diagram for fuel dispenser with external pump

The described column is characterized by high operational reliability: MTBF is at least 7000 hours. The use of modern electronic components, power electrical and hydraulic equipment provides it with a service life of at least 12 years, greatly simplifies maintenance and repair. Other advantages of the installation include:

- High accuracy: an error of no more than 0.5% at a minimum single dose.

- Productivity: not less than 50 l / min, and when using the high-speed channel more than 90 l / min.

- Security: the use of EC Dallas minimizes the risk of unauthorized interference in the operation of the fuel dispenser.

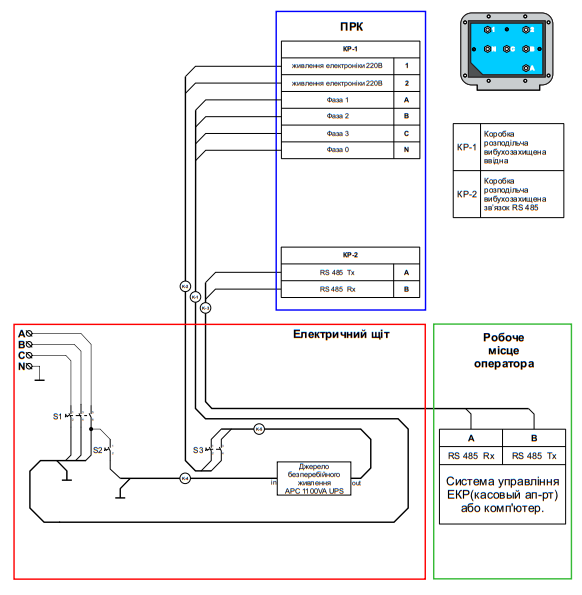

Electrical connection diagram

The fuel-distributing column of the Shelf 300-2 brand can be bought in basic execution or with additional equipment. Optionally, the unit is equipped with an LED display, a system for safe removal of fuel vapors and a remote pumping unit at the customer's choice.

Additional equipment:

- LED display

- OPW crane type

- Electric motor 220V

- Satellite

- High-speed channel with a capacity of 90 l / min.

Documentation

Certificates

- Conclusion of the state sanitary and epidemiological examination

- Permission to use the fuel dispenser

- Explosion protection certificate for electrical equipment

- Certificate of conformity of measuring instruments to the approved type

- Certificate of conformity

- Type examination certificate

- Fuel dispenser type inspection certificate

| Fuel dispenser specifications | |

| Nominal productivity, l/min | 50/90 |

| Error | ±0,5% |

| Minimum dose of fuel delivery, l | 2/10 |

| Number of taps | 4 |

| Electronic calibration | + |

| Number of pumps | 2 |

| Type of fuel | gasoline, dp, biodiesel (100%) or E15 |

| Working temperature | -25/+55°С |

| Powering | 230/400V +/- 10%, 50 Hz+/- 2Hz |

| User identification | ЕК Dallas |

| Hose length, m | 4 |

| Display | backlit LCD / LED |

| Total fuel counter | Electronic 12-digit |

| Single dose counter capacity | 9999,99 l |

| Dimensions H*W*D, mm, no more | 2300/1100/700 |

| Dimensions with packaging H*W*D, mm | 2450/1200/760 |

| Weight, kg, not more | 345, 296(without pumps) |

Tags: gas station, gas station, refueling, complex, additional equipment, performance, safe