GPS monitoring of diesel generators

We cannot imagine our life without electricity. Even minor power failures take us back to the Middle Ages. Today, most enterprises, plants, factories - install diesel generators, since force majeure with the power grid can lead to big problems and losses. According to the latest report from GlobalData, diesel generators are the most common backup power source, accounting for over 80% of the global generator market in 2017.

However, another problem arises: monitoring and maintenance of diesel generators. Monitoring diesel generators involves monitoring several parameters: fuel level, continuity of power supply and regularity of maintenance.

What does GPSM solve?

The GPSM system for diesel generators is designed to monitor fuel consumption and generator engine operating time, monitor the remaining fuel in the tank, determine the volumes of refueling and fuel draining, in addition, the system allows you to ensure uninterrupted fuel supply by controlling the pump when the specified fuel remains. Fuel consumption monitoring on diesel generators helps the operator to plan timely refueling and to detect and prevent theft, fuel draining from the tank or fuel line.

Diesel generator monitoring equipment:

✔️ GPSM tracker (from UAH 1565, diesel generators transmit parameters about their work via the GPRS channel to the monitoring server using a GPS tracker);

✔️ Pro Sensor fuel level sensor (from UAH 2999, a high-precision sensor measures the volume, level, refueling and draining of fuel in tanks);

✔️ Fuel level sensor display (UAH 1650, GPSM indicator displays accurate information about the level and volume of fuel, fuel level sensors connected to it, as well as average and hourly fuel consumption);

✔️ Fuel consumption sensor (Single-chamber from UAH 6430, Dual-chamber from UAH 8899. The price depends on the type of fuel system and engine power. The advantage is the most accurate way of recording fuel consumption on equipment that mainly works in one place).

Monitoring software

Local GPSM is a modern tool for GPS monitoring and control of fuels and lubricants, designed to track the location of objects, as well as control their parameters and status in real time. Saves parameters on the server for 365 days and exports data in different formats: Word, Excel, integration with 1C. Includes WEB interface and Android and IOS mobile applications.

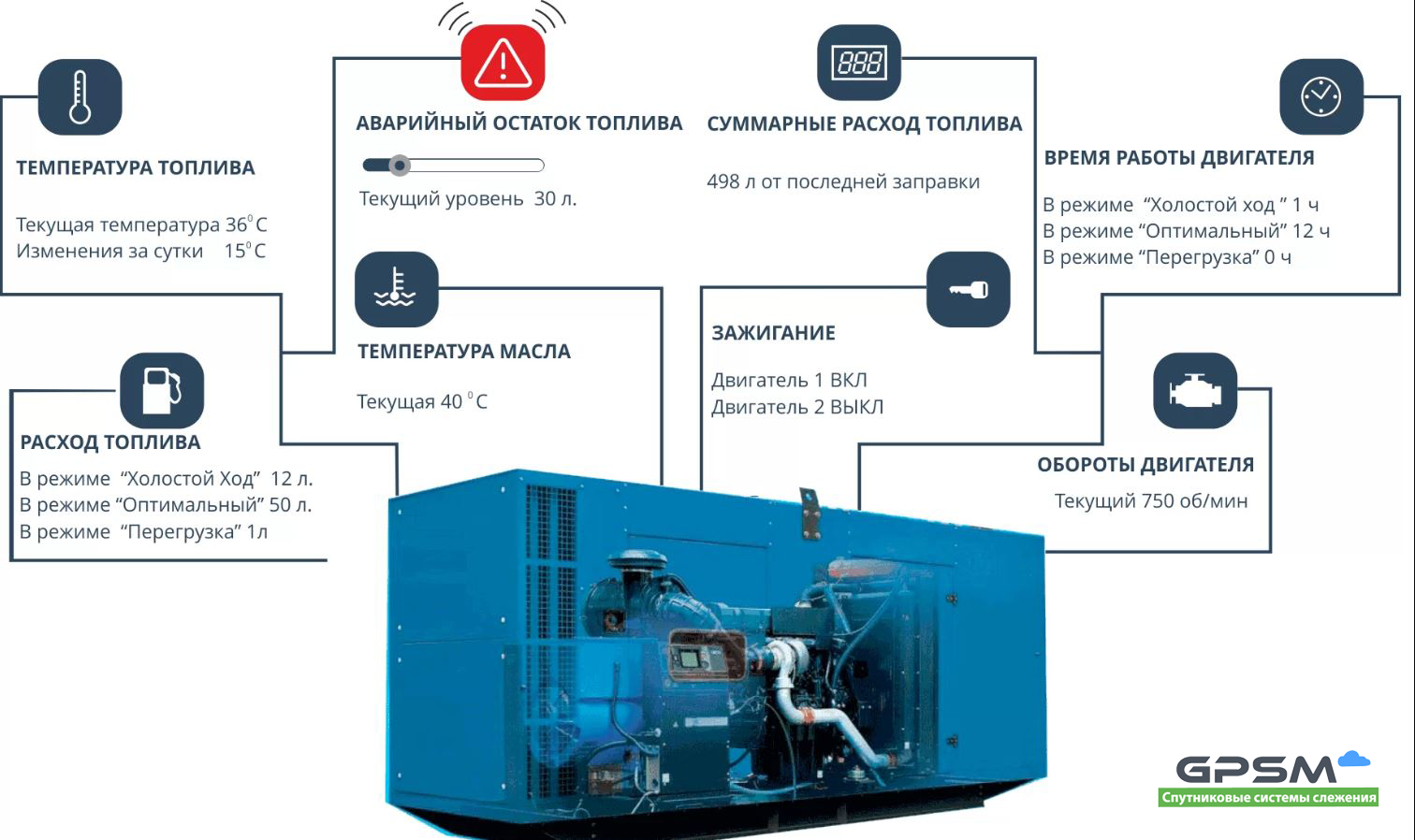

GPSM monitors diesel power plant parameters:

- currents in three phases;

- phase voltage in three phases;

- voltage frequency;

- full load power.

GPSM administers engine performance:

- revolutions;

- oil pressure;

- coolant temperature;

- starting battery voltage;

- number of starts;

- engine hours.

GPSM monitors fuel:

- level and volume of fuel in the tank;

- fuel consumption (in modes: idle, optimal, overload);

- notifies about refueling or fuel drains (number of liters, time and date).

GPSM generates reports for the requested period:

- diesel generator operating time;

- the amount of fuel consumed;

- total actual fuel consumption;

- total estimated costs for diesel fuel;

- average hourly fuel consumption;

- average fuel consumption per kW * hour;

- total energy consumption.

Example of a completed project

Given: Diesel generator

Objective: It is necessary to display the amount of fuel in liters, control fuel consumption, keep track of engine operating time, administer refueling, prevent the theft of fuel and lubricants by the company's employees. Also, the client needs to control the fuel reserves in the form of an alert on a smartphone in order to prevent an emergency stop.

Equipment: Installed GPS tracker GPSM Pro, display indicator, fuel level sensor Pro Sensor.

Implementation result:

GPSM will allow the dispatcher to remotely monitor the following diesel generator parameters:

- Engine load control;

- Engine speed control;

- Control of the output voltage;

- Engine temperature;

- Engine oil pressure;

- Fuel consumption;

- Engine running time;

- Object location, coordinates;

- Remote engine control.

Comments

Thanks!

Your comment has been sent.

Be the first to leave a comment here!